Compression Tube Fittings

Truelok® compression tube fittings, also known as double ferrule tube fittings or compression fittings are used in gas delivery systems, instrumentation, and other process control equipment. Compression tube fittings are manufactured in SS 316 Material. These tube fittings are extensively used in a variety of industrial applications, especially in Oil & Gas, Petroleum Refining, Power Generation, Chemical Processing, Semiconductor Manufacturing, Pulp & Paper, Research, and Bio-Technology. Pharmaceutical, Aerospace, and many other industries.

Truelok® compression tube fittings are designed and manufactured under a stringent Quality Assurance & Process Control System. These fittings provide cost-effective, reliable, and leakproof connections in Instrumentation and Process Control Sample Systems.

Compression tube fittings are essential components in various industries, playing a crucial role in creating leak-tight connections for fluid and gas systems. These fittings are designed to join and seal tubes or pipes, ensuring a secure and reliable flow of liquids or gases within a system. They are widely used in applications such as plumbing, automotive, aerospace, and hydraulic systems, among others.

The primary purpose of compression tube fittings is to connect tubes or pipes without the need for soldering, welding, or specialized tools. This makes installation easier and more efficient while reducing the risk of heat-related damage to the components. Compression fittings consist of several key elements, including a body, a compression nut, and a ferrule or olive. The tube is inserted into the fitting’s body, and as the compression nut is tightened onto the body, it compresses the ferrule against the tube, creating a tight seal.

One of the significant advantages of compression tube fittings is their versatility. They can be used with various tube materials, including copper, stainless steel, plastic, and brass, making them adaptable to a wide range of applications. Additionally, compression fittings can accommodate different tube sizes and shapes, offering flexibility in system design.

Leak prevention is a top priority in fluid and gas systems, and compression tube fittings excel in this regard. When properly installed, they provide a leak-free and reliable connection, ensuring the integrity of the system. This reliability is crucial in industries where safety and efficiency are paramount.

Compression tube fittings are indispensable components for creating secure and leak-tight connections in fluid and gas systems. Their versatility, ease of installation, and ability to prevent leaks make them a preferred choice in numerous industries, contributing to the overall efficiency and safety of various applications. Whether in plumbing, automotive, or aerospace, compression tube fittings play a vital role in ensuring smooth and trouble-free operation.

How do Compression Tube Fittings Work?

Compression tube fittings are essential components in plumbing and fluid systems, designed to create secure and leak-free connections between tubing and pipes. These fittings work by employing a compression mechanism to seal and join two pieces of tubing or pipe together.

At the heart of compression tube fittings is a nut and a ferrule (also known as an olive). The ferrule is a small, cylindrical piece typically made of brass or other durable materials, and it fits around the tubing or pipe. When the nut is tightened onto the fitting, it compresses the ferrule tightly against the tubing, creating a strong seal. This compression action effectively prevents leaks by blocking the escape of fluid between the fitting and the tubing.

The compression fitting’s design ensures that as you tighten the nut, the ferrule compresses uniformly around the tubing, evenly distributing pressure. This uniform compression is critical for creating a reliable and leak-resistant connection. Compression tube fittings are widely used in various applications, including plumbing, air compression systems, hydraulic systems, and more, where secure connections and fluid containment are crucial.

In summary, compression tube fittings work by using a nut and ferrule to compress and seal tubing or pipe, ensuring a tight, leak-free connection in fluid and gas systems.

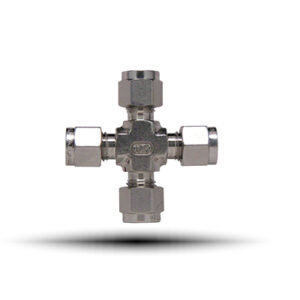

Types of Compression Tube Fittings

Compression tube fittings are essential components in various industries and applications where a secure and leak-free connection is crucial. These fittings are designed to join two or more tubes or pipes together, providing a reliable means of fluid or gas transfer. There are several types of compression tube fittings available, each tailored to specific needs and conditions.

- 1. Ferrule Fittings: These are the most common type of compression fittings. They consist of a nut and a front and back ferrule. When the nut is tightened, it compresses the ferrules onto the tube, creating a tight seal. These fittings are easy to install and provide a robust connection for a wide range of applications.

- 2. Bulkhead Fittings: These fittings are designed to pass through walls, panels, or barriers while maintaining a leak-free connection. They consist of two compression nuts and ferrules on either side of the barrier, ensuring a secure seal on both sides.

- 3. Union Fittings: Compression unions are used to connect two tubes of the same diameter. They consist of two nuts and two ferrules. When tightened, they create a leak-free connection between the tubes.

- 4. Elbow Fittings: These fittings have a 90-degree bend and are used to change the direction of tubing in a fluid or gas system. They come in various angles to suit specific layout requirements.

- 5. Tee Fittings: Compression tees are used to split a fluid or gas flow into two directions. They have a T-shaped design and are ideal for branching lines in plumbing and instrumentation systems.

- 6. Reducer Fittings: When you need to connect tubes of different diameters, compression reducer fittings are the solution. They consist of two ferrules and a nut and are available in various size combinations.

- 7. Cap Fittings: These fittings are used to seal off the end of a tube or pipe. They consist of a single nut and ferrule, creating a tight closure.

- 8. Check Valve Fittings: Check valves that allow fluid or gas to flow in one direction only. Compression check valve fittings incorporate this functionality into a compression fitting design, ensuring flow control and preventing backflow.

Compression tube fittings come in various types to accommodate the diverse needs of industries such as plumbing, HVAC, automotive, and industrial processes. Choosing the right type of compression fitting is essential to ensure a secure, leak-free, and efficient connection for your specific application.

Benefits of Compression Tube Fittings

Compression tube fittings offer numerous advantages in various industries and applications. Here are the key benefits of using compression tube fittings:

- 1. Leak-Free Sealing: Compression fittings provide a secure and leak-free connection, ensuring the integrity of fluid and gas systems. They create a tight seal by compressing the ferrule against the tubing.

- 2. Easy Installation: These fittings are user-friendly and straightforward to install without the need for specialized tools or soldering. This simplicity reduces labor costs and installation time.

- 3. Reusability: Compression fittings can be disassembled and reassembled multiple times without compromising their sealing performance, making them cost-effective in the long run.

- 4. Versatility: They are compatible with a wide range of materials, including copper, stainless steel, and plastic tubing, making them suitable for various applications in plumbing, HVAC, and industrial systems.

- 5. High Pressure and Temperature Tolerance: Compression fittings can handle high-pressure and high-temperature environments, making them ideal for critical applications where reliability is paramount.

- 6. Space-Efficient: These fittings have a compact design, which is especially beneficial in tight or confined spaces, allowing for efficient system layout and installation.

- 7. Resistance to Vibration: Compression fittings offer excellent resistance to vibration and mechanical stress, making them suitable for use in equipment and machinery.

- 8. Aesthetic Appeal: Their clean and professional appearance is favored in applications where aesthetics matter, such as in visible plumbing and gas systems.

In summary, compression tube fittings are a reliable, versatile, and efficient choice for various industries, providing secure connections and ensuring the smooth operation of fluid and gas systems.